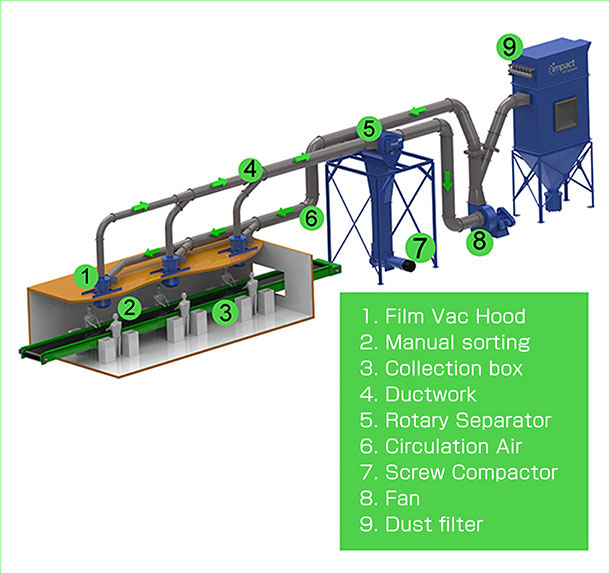

Film Vacuum System

The plastic FilmVac/material take off system offers the ultimate flexible solution for collecting and conveying handpicked material during the manual sorting process. The system consists of a series of specially designed material collection hoods which are typically mounted in the ceiling of the sorting cabin above the waste belts. The unique internal ‘Jetcone’ hood design uses a closed loop system to minimise operational noise levels and the amount of air withdrawn from the sorting cabin. Conveying air used to transport the material is recycled back through a return air system to significantly reduce the cabin make up air requirements. A series of collection hoods can be connected together via a range of ductwork, meaning all material is transported to a single point within the MRF, eliminating the need to duplicate material storage bunkers to match each hand picking location. Conveyed material is typically fed directly into a bale press to reduce material volumes, minimising labour and transport costs. The material is separated from the air stream via a specially adapted Impact rotary material separator and reverse jet filter system. The Impact material take off system has proven to be a highly valuea addition to the domestic waste recycling process, offering MRF designers maximum design flexibility and improved segregation of recyclables.

Benefits

● Systems designed for poly wrap, films, plastic bags and packaging or whole plastic bottles

● Multiple collection points can transport material back to single baler or storage bunkers

● Eliminates the need for duplicate storage bunkers

● When working in conjunction with a baler can substantially reduce material volumes, storage space and transport costs

● Ergonomically positioned for operator comfort and ease of access

● High material throughput capabilities

● Helps improve overall quality of other recyclables through removal of plastic contamination

● Quiet closed loop operation

Screw Compactor

A valuable addition to any film vacuum system, this simple design allows collected material to be compressed into an expanding plastic bag to produce a ‘sausage’ like bale. A single screw auger, discharge tube and retaining ring provide a simple yet highly reliable, cost effective solution to reduce bulky material into manageable volumes.

Benefits

● Few wear items, low maintenance and highly reliable

● Variable length bales to suit manual handling requirements

● No complicated wire tying systems